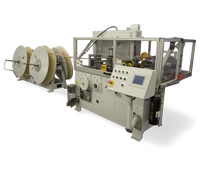

Return Elbow Bender

Oak India produces several different types of tube bending machines to suit your specific manufacturing requirements, including the Vertical Bend Hairpin Bender; Return Bender; Return, Elbow, Crossover Bender; and Return Elbow Bender. These machines are highly efficient in the production of various lengths and sizes of bent tubing. They generally consist of 3 sections: the bender, coil feeder and cutoff, and the coil stand. In the basic operation, level wound coils of tubing are fed through straightening rolls, cut to proper length, and then bent to varying degrees to produce the desired bend. Copper, Aluminum, Stainless Steel, and Titanium can all be formed with these machines.

Mechanical Return Bender

Oak India produces several different types of tube bending machines to suit your specific manufacturing requirements, including the Vertical Bend Hairpin Bender; Return Bender; Return, Elbow, Crossover Bender; and Return Elbow Bender. These machines are highly efficient in the production of various lengths and sizes of bent tubing. They generally consist of 3 sections: the bender, coil feeder and cutoff, and the coil stand. In the basic operation, level wound coils of tubing are fed through straightening rolls, cut to proper length, and then bent to varying degrees to produce the desired bend. Copper, Aluminum, Stainless Steel, and Titanium can all be formed with these machines.

Return Elbow Crossover Bender

Oak India produces several different types of tube bending machines to suit your specific manufacturing requirements, including the Vertical Bend Hairpin Bender; Return Bender; Return, Elbow, Crossover Bender; and Return Elbow Bender. These machines are highly efficient in the production of various lengths and sizes of bent tubing. They generally consist of 3 sections: the bender, coil feeder and cutoff, and the coil stand. In the basic operation, level wound coils of tubing are fed through straightening rolls, cut to proper length, and then bent to varying degrees to produce the desired bend. Copper, Aluminum, Stainless Steel, and Titanium can all be formed with these machines.

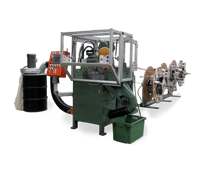

Return Bend Production Line

The Oak Return Bend Production Line combines three high production machines into one simple process. Tubing is bent, cleaned, sized, and rings are accurately and consistently placed—producing finished return bends. Production efficiency increases through decreased labor requirements. Reduced material handling and lifting improves safety and ergonomics.

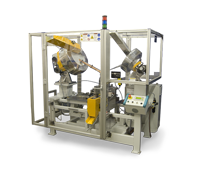

Size and Ring Machine

Oak India manufactures several types of return bend processing machines to suit your specific production requirements, including the Sizing and Ring Machine, Ring Machine, Sizing Machine, Rotary Sizing and Ring Machine, and Return Bend Cleaning System. This equipment can be used separately or, by incorporating conveyors, place in a continuous return bend production line.

Return Bend Cleaning Unit

Oak India manufactures several types of return bend processing machines to suit your specific production requirements, including the Sizing and Ring Machine, Ring Machine, Sizing Machine, Rotary Sizing and Ring Machine, and Return Bend Cleaning System. This equipment can be used separately or, by incorporating conveyors, place in a continuous return bend production line.