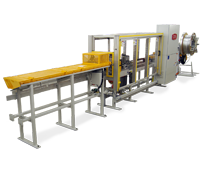

Fin Line

Each fin production line incorporates an Oak Fin Press along with an uncoiler, lubricator, fin die, and stacker/suction unit combination.

Fin Dies

Oak India has been the industry leader in designing and building fin dies . Our engineers will work closely with you to design and build your fin die to meet your specific heat transfer requirement. The dies can also be equipped with rapid die change options to provide more flexible and accurate production capabilities.

Oak India offers three main types of dies.

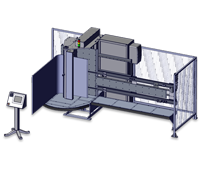

Tube Expanders

Oak India has a wide variety of expanders to meet your production needs. Oak Expanders come in all sizes, from single tube expanders to large horizontal expanders for your largest coils. We offer many options to customize your expander to your specific production requirements.

Tube Benders

Oak small bending machines turn out multiple bend angles easily and dependably. The cuts are straight and bend centers are accurate, protecting your investment in the quality of your final product.

Tube Cutoff

Oak india produces 3 types of cutoff machines. Two that process coil and straight tubing, while the third processes coiled multivoid (micro channel) tubing. We offer all cutoff styles in single or double configurations and with end-forming capabilities.

Coil Forms

Our Coil Form Machines produce high-quality bends in coils. Recent innovations have yielded the ability to make bends that were previously impossible from coils using very low-strength, enhanced fin designs. These coil forming machines will process single row coils or multiple single-row coils joined at one end.

Fin Line Equipment

The fin stock uncoiler, suction unit and stacker unit comprise the heart of the Burr Oak material handling system. The line equipment features new elements in stock feeding and fin collection geared toward ease of operation and increased productivity.